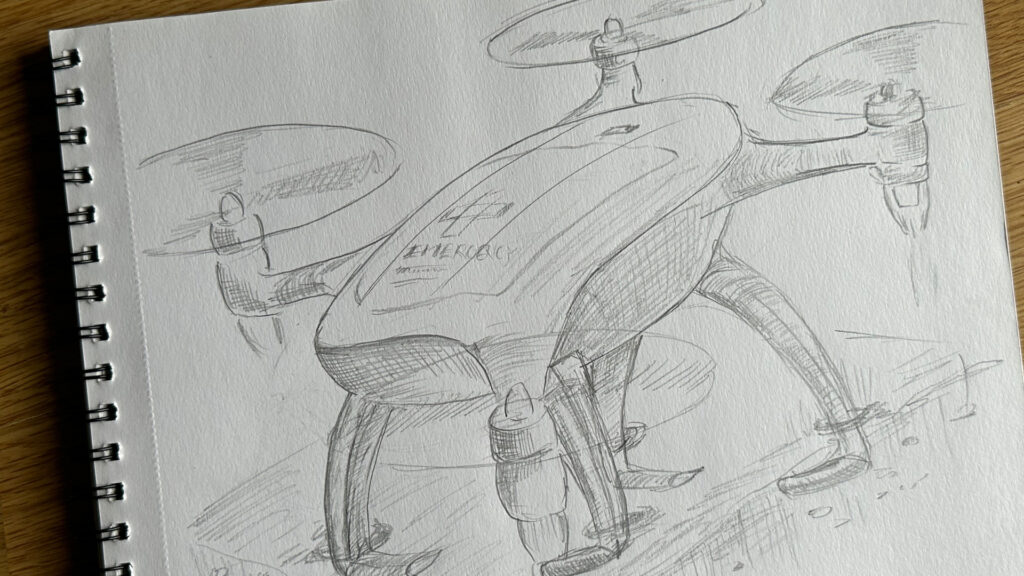

Water-Land Hybrid Drone

Manufacturing Process

1. Materials Selection:

Body: The drone’s body is manufactured from lightweight, corrosion-resistant materials such as carbon fiber or aerospace-grade aluminum to ensure durability and performance in both air and water environments.

Hydrofoils and Rotors: Made from high-strength composite materials to offer the best balance between weight and structural integrity.

2. Component Assembly:

Electronics Integration: Advanced sensors for navigation (GPS, LiDAR) and environmental monitoring (temperature, humidity, pH sensors) are integrated into the drone’s body. Waterproofing measures, including sealing and protective coatings, are applied to safeguard against water damage.

Propulsion System: The drone features a dual propulsion system. For air movement, it includes brushless motors with high-efficiency rotors. For water navigation, retractable hydrofoils equipped with miniature jet propulsion or propellers are installed.

Control System: A sophisticated onboard computer manages both flight and aquatic navigation, ensuring smooth transition between environments. This system is designed for autonomy with the capability for manual override via remote control.

3. Testing and Quality Assurance:

Rigorous testing in simulated and real-world environments to ensure operational reliability, durability in various weather conditions, and effective transition between air and water modes.

Technical Description

1. Performance Specifications:

Flight Range: Approximately 20 kilometers on a single charge.

Water Range: Up to 15 kilometers depending on current and conditions.

Speed: Capable of reaching speeds up to 60 km/h in the air and 25 km/h in water.

Endurance: Designed for up to 2 hours of continuous operation in air and 1.5 hours in water.

2. Features:

Adaptive Control System: Allows for seamless transition between flying and floating, adjusting the drone’s configuration in real-time based on environmental data.

Retractable Hydrofoils: Provide stability and efficiency in water, retracting during flight to reduce drag.

Modular Design: Enables quick replacement of components and upgrades, facilitating maintenance and customization.

3. Applications:

Ideal for a wide range of applications including but not limited to environmental monitoring, search and rescue operations, marine research, and aerial photography.