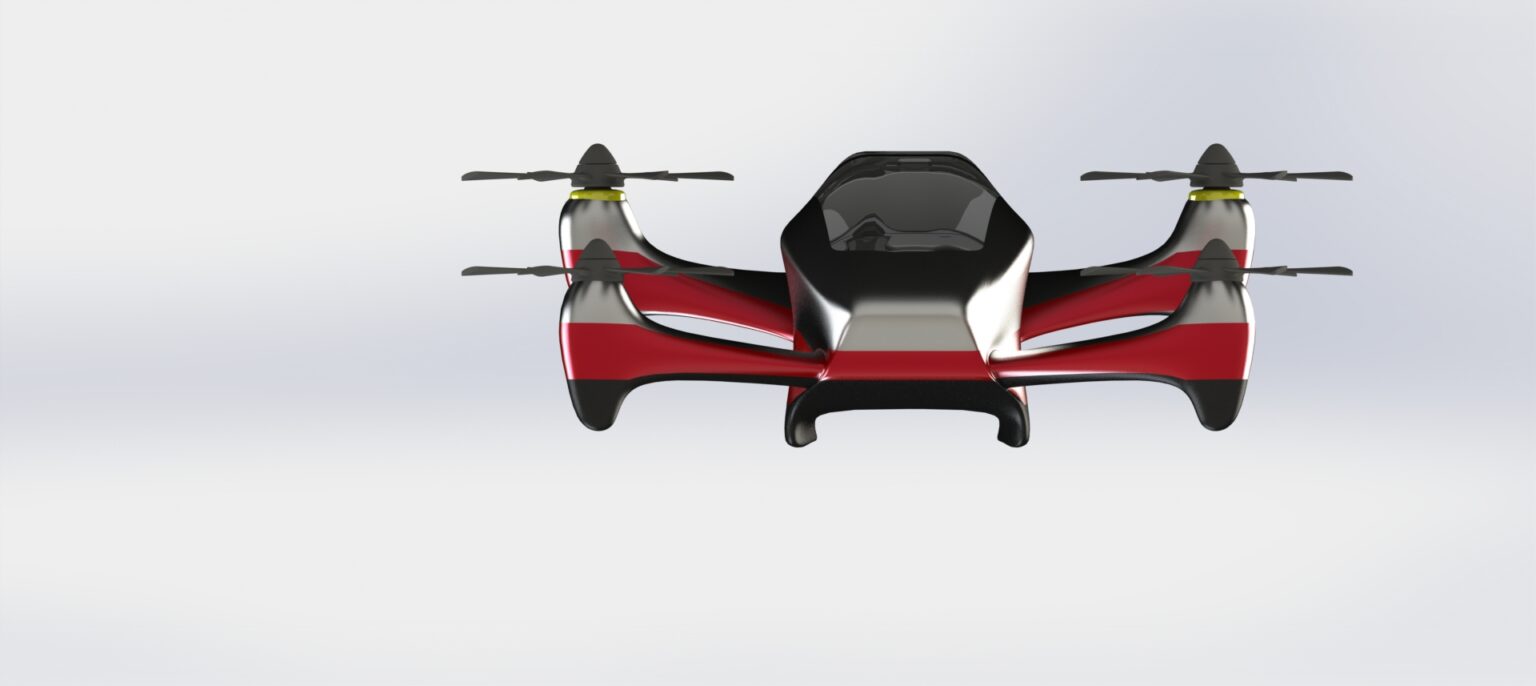

Personal Mobility Drone

Design Overview:

• Type: Personal Mobility Drone (PMD)

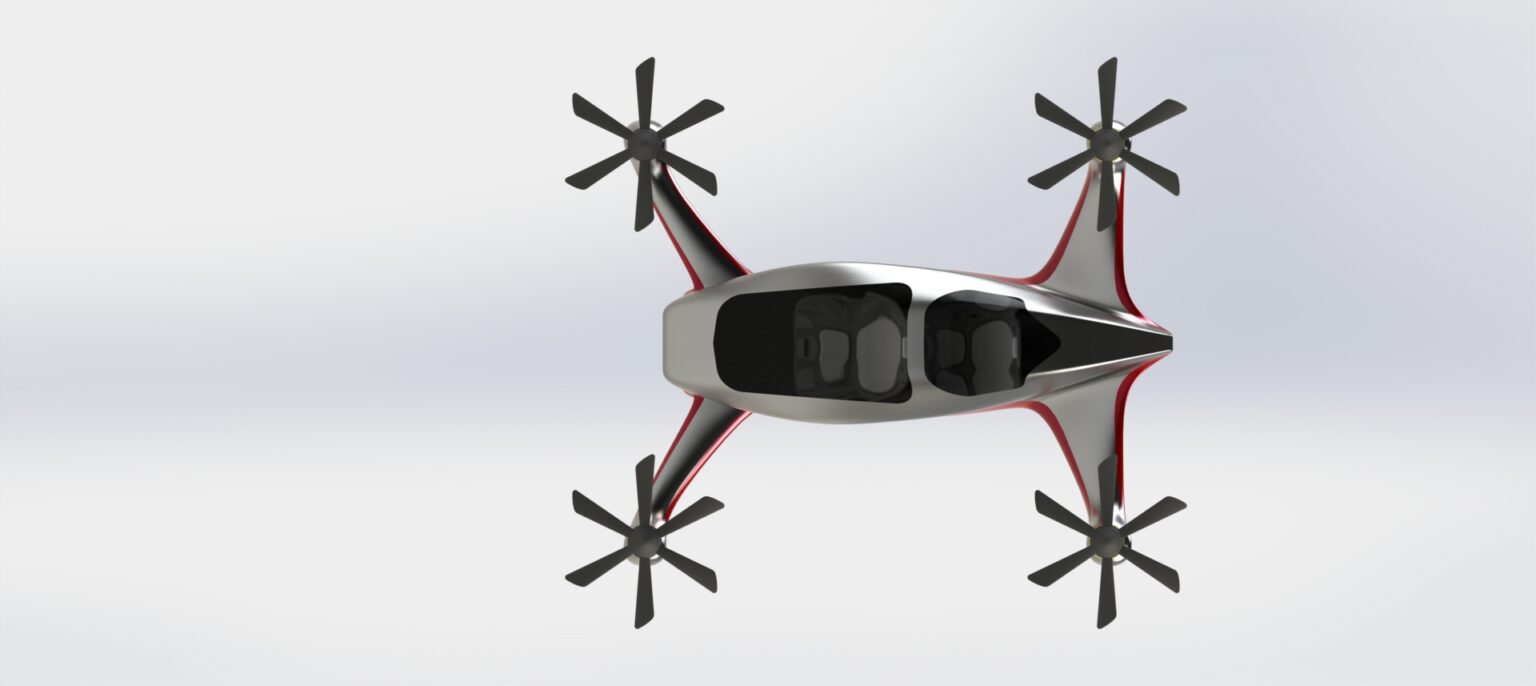

• Seating Configuration: Open, motorcycle-like seating for one individual, with ergonomic design for comfort and safety.

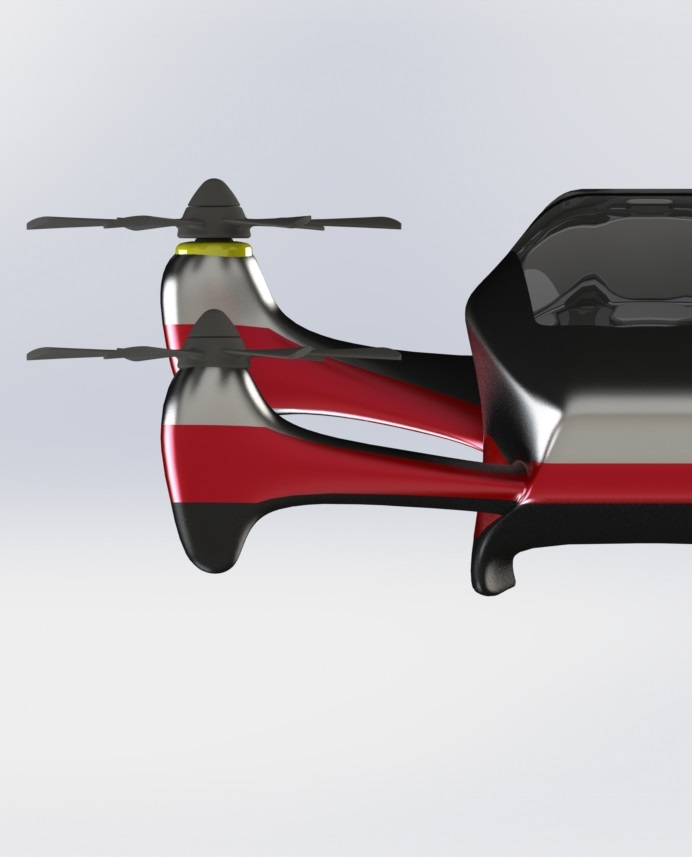

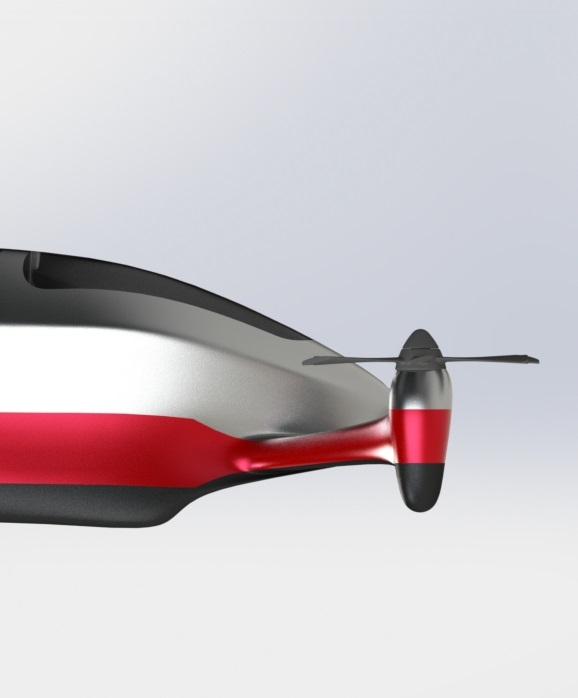

• Body Composition: High-strength, lightweight composite materials, including carbon fiber and aerospace-grade aluminum, for the frame and body. This provides an optimal balance between durability and weight reduction, essential for flight efficiency and maneuverability.

• Finish: Metallic red and black with chrome accents, utilizing advanced coating techniques for durability and resistance to environmental elements.

Propulsion and Navigation:

• Propellers: Four to eight electrically powered, brushless DC motors driving ultra-efficient propellers. These are designed for quiet operation and minimal vibration.

• Flight Control: Advanced flight control system with automatic stabilization, capable of manual and autonomous operation. Includes GPS and GLONASS for precise navigation and positioning.

• Safety Systems: Integrated roll cage around the seating area, smart collision avoidance technology using LIDAR and RADAR, and automatic emergency landing capabilities in case of system failure.

Communications and Interface:

• HUD (Heads-Up Display): Integrated into the helmet or goggles for displaying critical flight information, navigation, and communication alerts.

• Controls: Intuitive control system, allowing for both manual flight control via joystick or handlebars and voice-activated commands for hands-free operation.

• Connectivity: 5G and Wi-Fi for real-time data transfer, software updates, and communication with traffic management systems.

Manufacturing Process:

• Composite Fabrication: Use of automated fiber placement (AFP) machines for the creation of carbon fiber components, ensuring precision and strength.

• Assembly: Modular assembly line where major components (propulsion, energy system, body frame) are assembled in stages, followed by comprehensive systems integration testing.

• Quality Assurance: Rigorous testing for each unit, including wind tunnel testing, vibration analysis, and flight trials to ensure safety, reliability, and compliance with aviation standards.

Energy System:

• Power Source: High-density lithium-polymer (LiPo) battery pack, designed for quick charging and long endurance flights.

• Energy Management: State-of-the-art battery management system (BMS) to optimize performance, safety, and battery life.

Safety Certifications:

• Compliance with emerging urban air mobility (UAM) safety standards and regulations.

• Additional certifications for electrical safety, electromagnetic compatibility (EMC), and environmental impact.